SCR Projects – From Concept to Commissioning

We design and implement complete SCR projects – from construction and scheduling to successful commissioning.

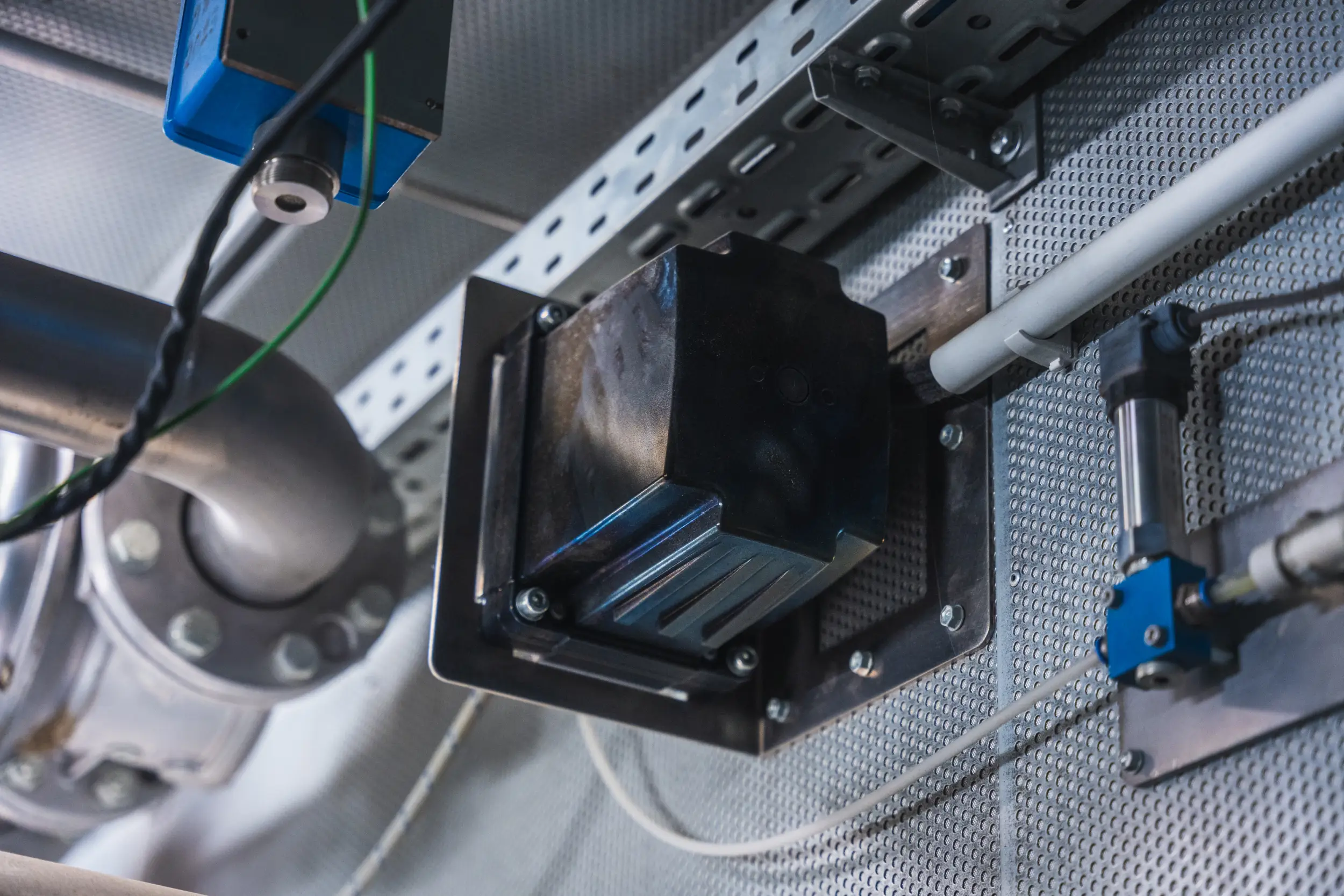

Compressed Air-Assisted Dosing System

Advantages of the compressed air-assisted SCR system:

- Precise dosing even at very high flow rates up to 120 l/h.

- Optimal atomization and mixing in large exhaust pipes.

- Homogeneous ammonia distribution for maximum conversion rates.

- Reliable operation even under variable load conditions.

Airless Dosing System

Advantages of the airless SCR system:

- Flexible dosing possible in two exhaust branches for twin-turbocharger systems.

- Easy maintenance and faster commissioning.

- Compact system design with fewer components and lower installation complexity.

- Energy-efficient, as no external compressed air supply is required.

For both systems: Thanks to ModBus TCP and potential-free contact relays, both systems can be easily integrated into any higher-level plant control system – ensuring smooth communication and full control.

Phone +49 4952 8997 225

Phone +49 4952 8997 225 Email info@inovacat.de

Email info@inovacat.de